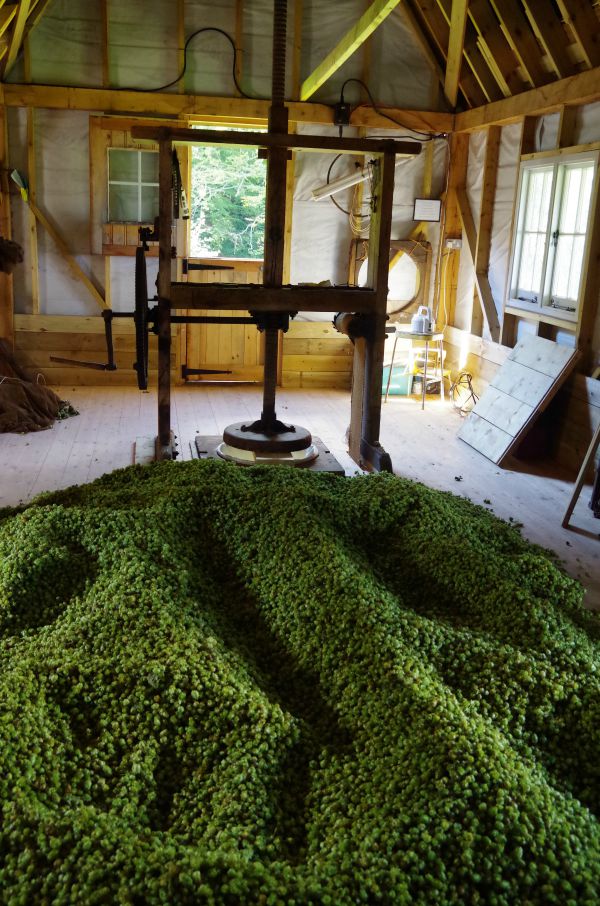

Whilst doing a casual ramble around the web searching for natural dyeing I found Donna Kallner’s Site. In it she mentioned her husband’s hop soda which he makes as well as his home brew beer. I was fascinated, all thoughts of dyeing quickly receded. I had never come across hop soda. I contacted Donna to ask her about it and she kindly came straight back with Bill’s recipe, which I pass on below.

Whilst doing a casual ramble around the web searching for natural dyeing I found Donna Kallner’s Site. In it she mentioned her husband’s hop soda which he makes as well as his home brew beer. I was fascinated, all thoughts of dyeing quickly receded. I had never come across hop soda. I contacted Donna to ask her about it and she kindly came straight back with Bill’s recipe, which I pass on below.

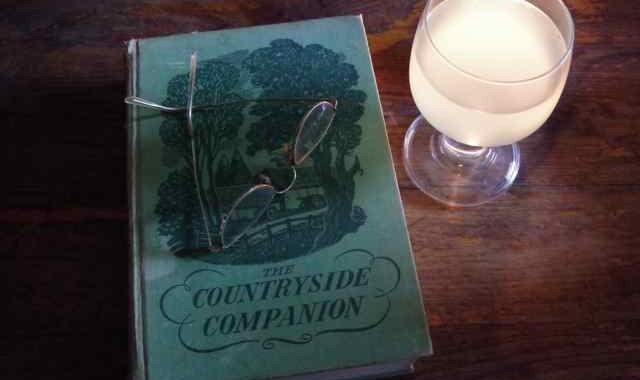

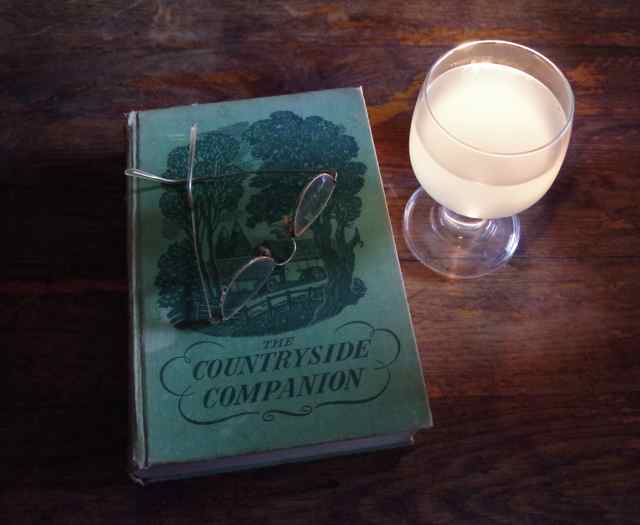

I made my first batch with Cascade hops, the result was lovely, a refreshing light grapefruity-flavoured drink, exactly as Donna described. My main criticism of this first attempt is that I did not leave the hops to steep quite long enough. Not wanting to mess it up I was too tentative hence had erred on the side of caution…. it could be a teensy bit stronger in flavour.

The hops are not boiled so I think this is what helps make it so fresh tasting. Next time I will be braver, add a few ‘marmalady’ Admiral hops to the Cascade hops and leave the them to infuse for a little longer than 2 days. Well just as per Bill’s instructions, ‘until the mix tastes right’ – exactly right, if all else fails follow the instructions!!

Thank you and Cheers to Bill and Donna – this recipe is definitely a keeper.

Bill’s Basic Hop Soda

(produces 1 gallon)

1-3 oz. hops (fresh or dry-packed and frozen)

2 cups sugar

1/8 to 1/4 teaspoon champagne yeast

One Step No-Rinse Cleanser

8-10 16-oz. plastic bottles and caps

Method

In a large non-reactive kettle (stainless steel) combine 1-3 oz. hops (fresh or dry-packed and frozen) in 2 cups water + 1 cup sugar + 1 T. lemon juice +1 T. lime juice and let soak for a few days until it tastes right (yep, that’s the recipe).

After soaking, use cheesecloth or a straining bag to filter out the solids.

Add 2 quarts water. Add lemon juice and lime juice and remaining 1 cup sugar now to taste.

Warm the liquid to 120-140 degrees for 10 minutes to kill any wild yeasts.

Cool the mixture to below 90 degrees. Add champagne yeast per packet instructions.

Use One Step No-rinse Cleanser to sterilize bottles, caps and bottling equipment (funnel and measuring cup)

Fill bottles with the cooled mixture and cap. Dent the plastic.

After 24 hours, start checking the bottles. When the dent is pushed out and the bottle feels firm, move the bottles to the refrigerator to slow the fermentation.

Cascade and Citra hop varieties make a grapefruity soda. Centennial has a bit more bite. I generally prefer a mixture.