Archives

A Journey from Brewing with Hops to Sewing with Hops

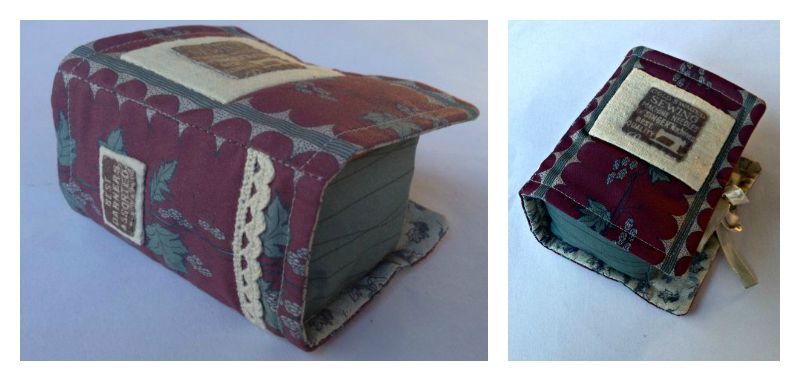

I recently attended a workshop with Amanda Hall of Monkey Buttons and I chose to make a ‘kangaroo’ bag. It was a great opportunity to trial run some of my toile fabric. I do like the teal green of this toile. Thank you Amanda for a super day, although we had a power cut from 12.30 to 3pm, we still managed to achieve a lot of sewing once we could use the machines again.

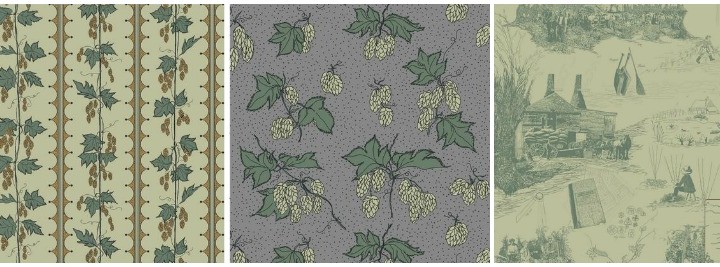

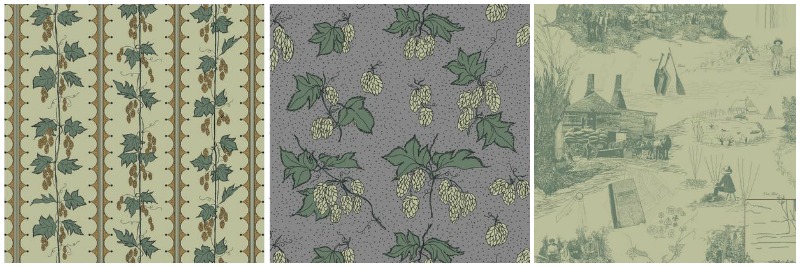

Because I am passionate about hops but also a quilter, I naturally began looking for hop themed fabrics as soon as I started quilting in 1999. I especially was looking out for a toile. When I did not find any that I liked, I started to play around doodling sketches of my own ideas. The design process was so enjoyable that I ended up with a range of 7 fabrics – the problem was how to get these drawings from the paper and printed onto fabric? I was very lucky with generous advise from Janet Clare as to how to submit your designs to a fabric company. Janet has her fabric available through Moda. I was naturally attracted to my favourite brands of fabrics and hoped to have one take up my designs but although I submitted them it was not to be. Basically I was told that whilst they liked the story the fan base for the subject would be too small for their huge print runs of 3000yds per design. However, now the designs were drawn up I knew it was something I truly believed in and there was no going back, I definitely did not want to throw the towel in at that point. So far that was the easy fun bit – the designs had to be put into a suitable format for uploading for printing.

My biggest thank you has to go to Sylvie Heasman of Art on Fabric for making my fabric possible to use in the first place.

Research on the internet for companies who print fabrics to order revealed a whole new world I knew almost nothing of. Then I happened on the profile of one of the resident designers for one company and read that she would also design on commission. Sylvie Heasman of ‘Art on Fabric’ . It was the was the ray of hope I was looking for but it meant taking what was a huge leap of faith, I had to put my complete trust into someone who was then a total stranger. However it was either do that or forever wonder ‘maybe, what if…..’ and that was not an option. The risk had to be taken and Sylvie’s profile felt right, so I took a deep breath and emailed her.

Sylvie kindly agreed to put my hops designs into the right digital format for uploading to the printers computer system. She performed the ‘ta da abracadabra’ and viewing on line still has that ‘as if by magic’ feeling, I could not have done this and am eternally grateful to Sylvie for her patience and skill. It is still a thrill to make something with the fabric I designed which has only been made possible by Sylvie’s skill. I can honestly recommend to anyone who has a design idea in their head, to contact Sylvie who will make it happen for you. The fabric printers Woven Monkey have been excellent too, even with my limited IT skills their site is easy to use. The variety of fabric types to choose from and their colours are also a joy.

See my full range of hops inspired fabrics available in various colourways at Woven Monkey.

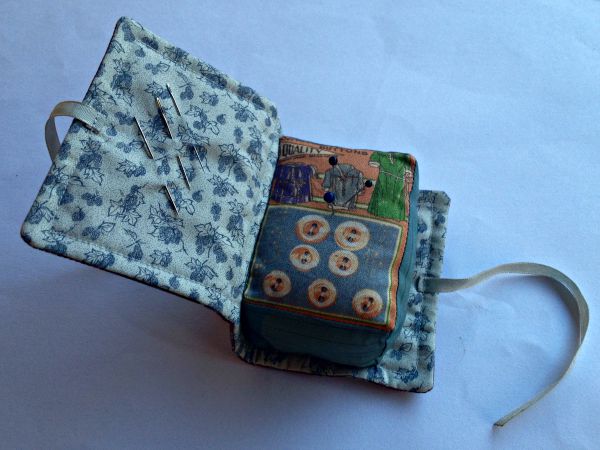

Mystery Item

I mentioned that I had received 2 gifts both of which were prototypes, the first was my beautiful 1/2 bushel trug shown last time and now in full service, the second I will reveal at the end of October.

For now here is a peek of part of it, I wonder if anyone can guess what the item is…?

1/2 Bushel Traditionally Dried Hops for Home Brewing

When purchasing a trug you want the real McCoy, sturdy and beautiful, but also supremely practical to use.

The genuine article is made in Sussex with cleaved sweet chestnut and cricket bat willow, it will last a lifetime. This is recycling at it best, made with left over willow from local cricket bat makers and sweet chestnut from coppiced woodland in the area. Even the left over shavings from making the trugs are used, nothing is wasted. There are cheaper ply wood impostors on the market, but their price is really their only attraction. They may be trug shaped, and yes some are made in Sussex but they are not made with the traditional materials and like the old saying goes “you can’t make a silk purse out of a sow’s ear”, the real deal is the real thing.

I am super fortunate to live relatively close to two master trug makers Richard Bingham who made the bushel trug pictured earlier on this website with my fabric in and Charlie Groves who has his own shop near Lewes in East Sussex. The bushel trug is not easy to find as it needs much longer lengths of cricket bat willow than are normally available for the boards. It does not have feet. It is a very workmanlike size originally made for farm produce, we used one for many years to measure corn for tipping into an old Massey Ferguson drill.

I mentioned earlier this month that I had received 2 super exciting surprise gifts, each being a prototype. One of these was a half bushel trug from Charlie which was the prototype for the limited edition of trugs produced especially for the 2015 Chelsea Flower Show ‘A Trugmakers Garden’ which won a coveted Gold Medal.

1/2 Bushel Traditionally Dried Hops for Home Brewing

1/2 Bushel Traditionally Dried Hops for Home Brewing

During Chelsea, Charlie was present with Sarah from the Truggery at Herstmonceux to demonstrate trug making on site. The half bushel trug has feet but the shape is much deeper than usual and the actual ‘basket’ has 11 boards instead of the normal 5 or 7 .depending on size. It was made as a copy of an old one found in a redundant farm building. You can read about the discovery of the old bushel trug here.

Professional trug makers like many other specialist craftsmen do not find it easy to make a living from their craft and as such are a dying breed (There are only 5 craftsmen in the world left now making traditional Sussex trugs). Proactively, to try to redress this trend they have joined forces to apply for official certification. If successful they will then be able to give a guarantee that their produce is the genuine article. This will hopefully cull out any interlopers and highlight the cheap copies on the market.

For further reading about Sussex Trugs & trug makers this recent (16th September 2015) article in COUNTRY LIFE magazine is worth a read – “The Great Trug Revival” by Tessa Waugh. Digital editions are available via the Country Living website.

Hop Shop is Open!

If you want to buy hops that were traditionally grown, specifically for the British craft brewer – Our 2015 hop harvest is ready to ship now!

Head over to our Hop Shop, varieties available this season include: Admiral Hops, Bramling Cross Hops, Cascade Hops, Goldings Hops, Phoenix Hops, Pilgrim Hops and Target hops.

Some of our hop varieties are in limited quantities so it will be on a first come first served basis this first year.

We guarantee freshness – our hops, once packaged will not be stored to be sold the following year.

Sewing with Hop Fabrics

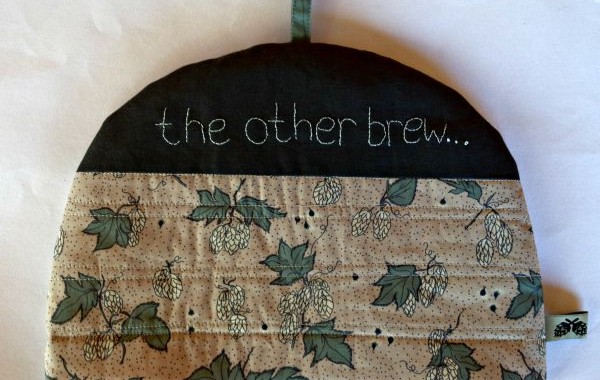

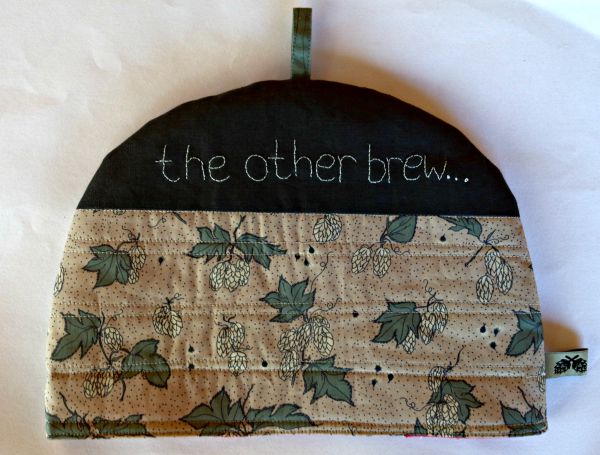

Since my daughter & son in law, Nova & Andy emigrated to live in Australia 15 years ago, Nova has always said she has got used to the hot Christmases and other key dates except for September. Having been brought up on a hop farm September is and always will mean only one thing…… ‘hop picking’ and heralding the start of autumn. So with this in mind I sent Nova some of my new ‘hoppy’ fabrics to play with hoping she would have fun with them and a mini hop picking celebration of her own. This is what she has made with the bits and pieces in the mixed bunch of hop fabrics.

The t-cosy made me smile and the little pincushion so sweet. Thank you Nova for sharing!

The t-cosy made me smile and the little pincushion so sweet. Thank you Nova for sharing!

Hop fabrics available here & the book pincushion pattern is available from Patchwork Pottery.

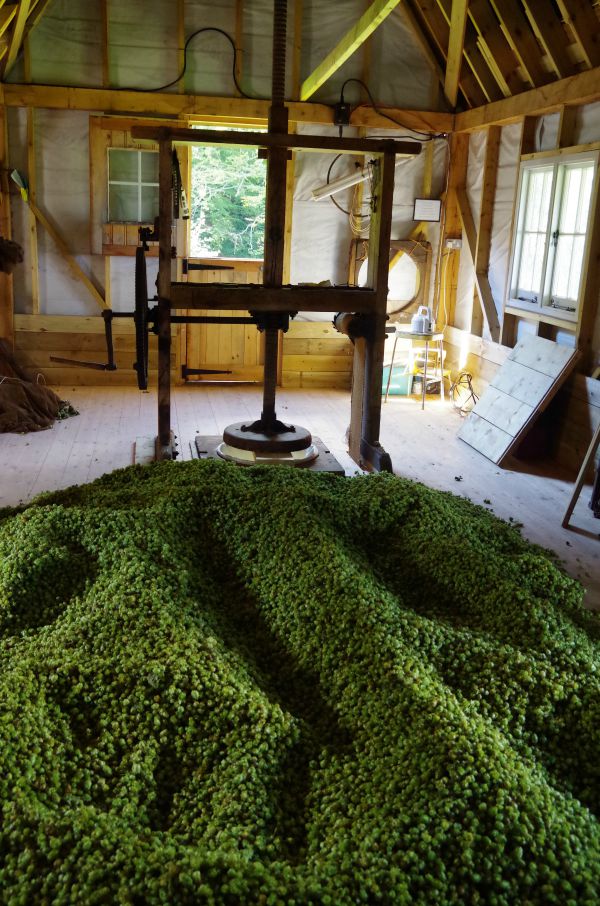

Traditional Charcoal Drying of Cascade Hops

In preparation for this first traditional charcoal drying of the Cascade hops, locally made charcoal had already been sourced and collected during the summer. All other hop varieties had been picked and dried with an oil fired drying unit in the usual way used by growers today. The late variety Cascade hops had been ear marked for this initial trial drying traditionally with charcoal.

When the hops were picked last weekend, the weather turned out to be perfect for this first trial drying, it was a dry and clear day with a light breeze running. After the preceding wet week this felt like a good omen.

There is only so much you can pick up from old books and hearsay from the very few remaining people who can remember cascade hops being dried with coal and charcoal kilns. Basically it had to be a practical hands on, ‘go for it’ , learning on the job experience. Of course it will take several burns before I become familiar with the many aspects of the furnace and the nuances of how the new oast behaves in different atmospheric conditions.

The hops were loaded very shallowly compared to their oil dried counterpart loads but carefully raked level in the same way. I use a solid fuel rayburn to cook with so was hoping that this would stand me in good stead here. The fire was lit and because this was a venture into unknown territory, the size and heat gradually increased until the correct temperature was reached. Literally testing the temperature! It was a surprise how quickly the temperature in the kiln responded to any alterations with the draft.

As the hops were approaching being dry the fire was allowed to die down before unloading them onto the cooling floor then as for any other load left for a time before being pressed.

As the hops were approaching being dry the fire was allowed to die down before unloading them onto the cooling floor then as for any other load left for a time before being pressed.

Have I already learnt masses? Yes of course and would I try things a little differently next time? Well again yes, I will make a few small changes, but certainly nothing dramatic especially for another year yet. And as for the finished article I am very happy with how things turned out with this initial trial drying.

Have I already learnt masses? Yes of course and would I try things a little differently next time? Well again yes, I will make a few small changes, but certainly nothing dramatic especially for another year yet. And as for the finished article I am very happy with how things turned out with this initial trial drying.

If you’d like to try some of these traditionally dried Cascade hops in your next brew, visit the Hop Shop now as we only have a very limited quantity this year.